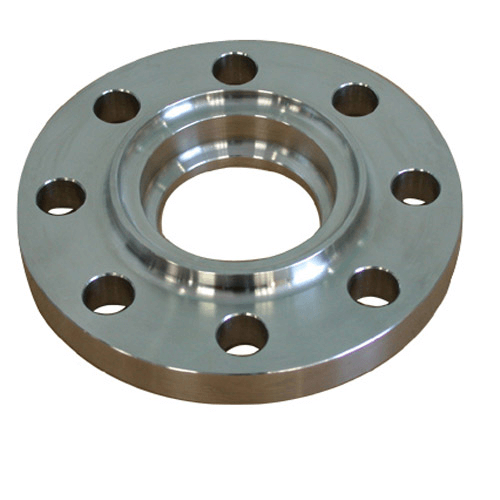

Stainless Steel 17-4 PH Flanges

UNS S17400 Screwed Flanges, ASME SA182 SS 17-4 PH Spectacle Blind Flanges, SS 17-4 PH Weld Neck Flanges A/ B, DIN 1.4542 Reducing Flanges, DIN 1.4542 Threaded Flanges, DIN 1.4542 Ring Type Joint Flanges.

About Stainless Steel 17-4 PH Flanges

The chemical components used to make stainless steel 17-4 PH flanges include chromium, nickel, manganese, carbon, phosphorus, sulfur, and iron. These steel flanges’ physical and mechanical characteristics include density, elongation, thermal and electrical conductivity, modulus of expansion, yield strength, and tensile strength. The grade, standard, and tolerance are requirements for making these steel flanges. Shape, size, dimensions, steel flange surface, type, intended use, and forms are all important factors.

Uses of stainless steel 17-4 PH flanges: :

Offshore oil drilling firms, chemical products, electricity production, petrochemical industry, food manufacturing, heat exchanger, paper, pulp, thermal treatments, condensing, and pharmaceutical sectors are just a few industries that can use stainless steel 17-4 PH flanges. Additionally, these flanges may be used for a wide range of general applications, including marine equipment, sewage disposal, heat oxidizers, storage, refining, and aircraft piston engine manifolds.

Properties of stainless steel 17-4 PH flanges:

- Flanges constructed of DIN 1.4542 are created by combining fabrication, welding, and enhanced corrosion-resistance techniques.

- The most significant use for these steel flanges is heat processing. These stainless steel flanges, often used in gauge segments, contain increased carbon concentrations to prevent distortion.

- These flanges are designed to be utilized in all corrosion situations, such as acid storage, and are functional in contaminated areas. These flanges are resistant to crevice corrosion, stress cracking corrosion, chloride pitting corrosion, and all other types of corrosion.

- These flanges are magnetic when they are being welded but are nonmagnetic when they are annealed. Although chloride surroundings are the best, these flanges may be utilized in chemical conditions.

- The stainless steel used to make UNS S17400 flanges is precipitation-hardened, renowned for its high strength and capacity to preserve mechanical qualities up to 600°F.

- The yield strength of these flanges is more than 4 times powerful than that of 316 stainless steel. The elastic modulus of 17-4 PH can be up to 2-12 times higher than that of Duplex 2205 flanges.

- It has good fabrication properties and can be age-hardened with a single thermal treatment between 900 and 1150 °F.

- Grade 17-4 PH flanges must be delivered in either the solution-annealed or age-hardened state. To age harden 17-4 PH, two processes are typically involved: solution treatment, quenching, and then aging for precipitation hardening.

Testing of the flanges produced :

The following tests are carried out to evaluate the steel flanges’ quality:

- An atmospheric pressure test,

- Micro and macro test

- Hydrostatic test

- Raw Material test

- Hardness test

- Chemical and mechanical testing test

- Positive substance identification

Stainless Steel 17-4 PH Blind Flange Stockist, SS 17-4 PH Longweld Neck Flange Supplier, UNS S17400 Lap Joint Flanges Manufacturer.

Specification of Stainless Steel 17-4 PH Flanges

| Specification | ASTM A182 / ASME SA182 |

| Dimension Standard | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| DIN Flanges | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. |

| JIS Flanges | JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K |

| BS Flanges | BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H. |

Ready stock of Flanges available for Stainless Steel 17-4 PH Flanges

Equivalent Grades of Stainless Steel 17-4 PH Flanges

| STANDARD | WERKSTOFF NR. | UNS |

| SS 17-4 PH | 1.4542 | S17400 |

Chemical Composition of Stainless Steel 17-4 PH Flanges

| Grade | C | Cb+Ta | Cr | Cu | Fe | Mn | Ni | P | S | Si |

| SS 17-4 PH | 0.07 max | 0.15-0.45 | 15.00-17.50 | 3.00-5.00 | Bal | 1.0 max | 3.0-5.0 | 0.40 max | 0.03 max | 1.0 max |

Mechanical Properties of Stainless Steel 17-4 PH Flanges

| Grade | Tensile Strength ksi (MPa) | Yield Strength 0.2% ksi (min) | Elongation % | Hardness (Rockwell) MAX |

| SS 17-4 PH | 170000 psi | 140000 psi | 6% | 38 |

Other Types of Flanges of Stainless Steel 17-4 PH Flanges

Dimensions Standard Of Stainless Steel 17-4 PH Flanges

| Nominal Size | Outside Diameter (OD) | Min. Thickness (T) | RF Dia. (R) | No. of Bolt Holes | Diameter of Holes | Bolt Circle (BC) | SO Bore ID (SB) | WN Bore ID (WB) | Dia. Hub Base (HB) | Dia. of Hub Top (HT) | SO LTH (SL) | WN LTH (WL) |

| 1⁄2 | 3.50 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.50 | 1.05 | 0.56 | 2.00 |

| 1 | 4.25 | 0.50 | 2.00 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.50 | 4 | 0.62 | 3.50 | 1.70 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5.00 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.90 | 0.81 | 2.38 |

| 2 | 6.00 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7.00 | 0.81 | 4.12 | 4 | 0.75 | 5.50 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.50 | 0.88 | 5.00 | 4 | 0.75 | 6.00 | 3.57 | 3.07 | 4.25 | 3.50 | 1.12 | 2.69 |

| 31⁄2 | 8.50 | 0.88 | 5.50 | 8 | 0.75 | 7.00 | 4.07 | 3.55 | 4.81 | 4.00 | 1.19 | 2.75 |

| 4 | 9.00 | 0.88 | 6.19 | 8 | 0.75 | 7.50 | 4.57 | 4.03 | 5.31 | 4.50 | 1.25 | 2.94 |

| 5 | 10.00 | 0.88 | 7.31 | 8 | 0.88 | 8.50 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11.00 | 0.94 | 8.50 | 8 | 0.88 | 9.50 | 6.72 | 6.07 | 7.56 | 6.63 | 1.50 | 3.44 |

| 8 | 13.50 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16.00 | 1.12 | 12.75 | 12 | 1.00 | 14.25 | 10.88 | 10.02 | 12.00 | 10.75 | 1.88 | 3.94 |

| 12 | 19.00 | 1.19 | 15.00 | 12 | 1.00 | 17.00 | 12.88 | 12.00 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21.00 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14.00 | 2.19 | 4.94 |

| 16 | 23.50 | 1.38 | 18.50 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18.00 | 16.00 | 2.44 | 4.94 |

| 18 | 25.00 | 1.50 | 21.00 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18.00 | 2.62 | 5.44 |

| 20 | 27.50 | 1.62 | 23.00 | 20 | 1.25 | 25.00 | 20.20 | 19.25 | 22.00 | 20.00 | 2.81 | 5.62 |

| 22 | 29.50 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22.00 | 3.07 | 5.82 |

| 24 | 32.00 | 1.81 | 27.25 | 20 | 1.38 | 29.50 | 24.25 | 23.25 | 26.12 | 24.00 | 3.19 | 5.94 |

Size Of Stainless Steel 17-4 PH Flanges

| Nom. Pipe Size | o | T1 | R | x | No.2/Dia. of Holes | Bolt Circle Dia. | L21 | H | B23 | L | B | r | L34 | B3 | D |

| 1/2 | 3.50 | 0.44 | 1.38 | 1.19 | 4-0.62 | 2.38 | 1.88 | 0.84 | 0.62 | 0.62 | 0.88 | 0.12 | 0.62 | 0.90 | 0.38 |

| 3/4 | 3.88 | 0.50 | 1.69 | 1.50 | 4-0.62 | 2.75 | 2.06 | 1.05 | 0.82 | 0.62 | 1.09 | 0.12 | 0.62 | 1.11 | 0.44 |

| 1 | 4.25 | 0.56 | 2.00 | 1.94 | 4-0.62 | 3.12 | 2.19 | 1.32 | 1.05 | 0.69 | 1.36 | 0.12 | 0.69 | 1.38 | 0.50 |

| 1-1/4 | 4.62 | 0.62 | 2.50 | 2.31 | 4-0.62 | 3.50 | 2.25 | 1.66 | 1.38 | 0.81 | 1.70 | 0.19 | 0.81 | 1.72 | 0.56 |

| 1-1/2 | 5.00 | 0.68 | 2.88 | 2.56 | 4-0.62 | 3.88 | 2.44 | 1.90 | 1.61 | 0.88 | 1.95 | 0.25 | 0.88 | 1.97 | 0.62 |

| 2 | 6.00 | 0.75 | 3.62 | 3.06 | 4-0.75 | 4.75 | 2.50 | 2.38 | 2.07 | 1.00 | 2.44 | 0.31 | 1.00 | 2.46 | 0.69 |

| 2-1/2 | 7.00 | 0.88 | 4.12 | 3.56 | 4-0.75 | 5.50 | 2.75 | 2.88 | 2.47 | 1.12 | 2.94 | 0.31 | 1.12 | 2.97 | 0.75 |

| 3 | 7.50 | 0.94 | 5.00 | 4.25 | 4-0.75 | 6.00 | 2.75 | 3.50 | 3.07 | 1.19 | 3.57 | 0.38 | 1.19 | 3.60 | 0.81 |

| 3-1/2 | 8.50 | 0.94 | 5.50 | 4.81 | 8-0.75 | 7.00 | 2.81 | 4.00 | 3.55 | 1.25 | 4.07 | 0.38 | 1.25 | 4.10 | 0.88 |

| 4 | 9.00 | 0.94 | 6.19 | 5.31 | 8-0.75 | 7.50 | 3.00 | 4.50 | 4.03 | 1.31 | 4.57 | 0.44 | 1.31 | 4.60 | 0.94 |

| 5 | 10.00 | 0.94 | 7.31 | 6.44 | 8-0.88 | 8.50 | 3.50 | 5.56 | 5.05 | 1.44 | 5.66 | 0.44 | 1.44 | 5.69 | 0.94 |

| 6 | 11.00 | 1.00 | 8.50 | 7.56 | 8-0.88 | 9.50 | 3.50 | 6.63 | 6.07 | 1.56 | 6.72 | 0.50 | 1.56 | 6.75 | 1.06 |

| 8 | 13.50 | 1.12 | 10.62 | 9.69 | 8-0.88 | 11.75 | 4.00 | 8.63 | 7.98 | 1.75 | 8.72 | 0.50 | 1.75 | 8.75 | 1.25 |

| 10 | 16.00 | 1.19 | 12.75 | 12.00 | 12-1.00 | 14.25 | 4.00 | 10.75 | 10.02 | 1.94 | 10.88 | 0.50 | 1.94 | 10.92 | 1.31 |

| 12 | 19.00 | 1.25 | 15.00 | 14.38 | 12-1.00 | 17.00 | 4.50 | 12.75 | 12.00 | 2.19 | 12.88 | 0.50 | 2.19 | 12.92 | 1.56 |

| 14 | 21.00 | 1.38 | 16.25 | 15.75 | 12-1.12 | 18.75 | 5.00 | 14.00 | 13.25 | 2.25 | 14.14 | 0.50 | 3.12 | 14.18 | 1.63 |

| 16 | 23.50 | 1.44 | 18.50 | 18.00 | 16-1.12 | 21.25 | 5.00 | 16.00 | 15.25 | 2.50 | 16.16 | 0.50 | 3.44 | 16.19 | 1.75 |

| 18 | 25.00 | 1.56 | 21.00 | 19.88 | 16-1.25 | 22.75 | 5.50 | 18.00 | 17.25 | 2.69 | 18.18 | 0.50 | 3.81 | 18.20 | 1.94 |

| 20 | 27.50 | 1.69 | 23.00 | 22.00 | 20-1.25 | 25.00 | 5.69 | 20.00 | 19.25 | 2.88 | 20.20 | 0.50 | 4.06 | 20.25 | 2.13 |

| 22 | 29.50 | 1.81 | 25.25 | 24.25 | 20-1.38 | 27.25 | 5.88 | 22.00 | 21.25 | 3.13 | 22.22 | 0.50 | 4.25 | 22.25 | 2.38 |

| 24 | 32.00 | 1.88 | 27.25 | 26.12 | 20-1.38 | 29.50 | 6.00 | 24.00 | 23.25 | 3.25 | 24.25 | 0.50 | 4.38 | 24.25 | 2.50 |

Weight Chart Of Stainless Steel 17-4 PH Flanges

| Standard Of Flanges | Class Of Flanges | Diameter Of Flanges | Diameter Of Bolt Circle | Bolts Number | Size Of Bolt | Bolt Hole Diameter |

| AS4087 Flanges | PN14 Flanges | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C Flanges | 95 | 67 | 4 | 13 | 14 |

| Table D Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table E Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table F Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table H Flanges | 114 | 83 | 4 | 16 | 17 | |

| Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

| PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Pressure Rating Of Stainless Steel 17-4 PH Flanges

| Temp. ℃ | Pressure-ASME temperature rating for B16.47 by class, bar | |||||

| 75 | 150 | 300 | 400 | 600 | 900 | |

| -29 to 38 | 10.0 | 20.0 | 51.7 | 68.9 | 103.4 | 155.1 |

| 50 | 9.8 | 19.5 | 51.7 | 68.9 | 103.4 | 155.1 |

| 100 | 8.8 | 17.7 | 50.7 | 67.5 | 101.3 | 152.0 |

| 150 | 7.9 | 15.8 | 45.9 | 61.2 | 91.9 | 137.8 |

| 200 | 6.9 | 13.8 | 42.7 | 56.9 | 85.3 | 128.0 |

| 250 | 6.0 | 12.1 | 40.5 | 53.9 | 80.9 | 121.4 |

| 300 | 5.1 | 10.2 | 38.9 | 51.8 | 77.7 | 116.6 |

industrial use flanges for Stainless Steel 17-4 PH Flanges

Price Of Stainless Steel 17-4 PH Flanges

| Stainless Steel Forged Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Blind Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Slip On Flange | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Socketweld Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

| Stainless Steel Long Weld Neck Flanges | USD $2.05 - $10.06 / Piece (FOB Price) on request |

Application Of Stainless Steel 17-4 PH Flanges

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Stainless Steel 17-4 PH Flanges

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

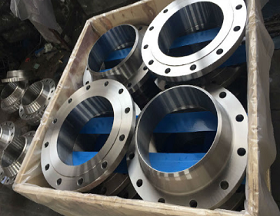

Packing Of Stainless Steel 17-4 PH Flanges

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

DIN 1.4542 RTJ Flanges Catalogue, 17-4 PH SS Flat Flanges Weight Calculator, DIN 1.4542 Forging Facing Flanges Price List In India, UNS S17400 Orifice Flanges Weight Chart, 17-4 PH SS Spades Ring Spacers Flanges Price Per Kg, SS 17-4 PH Slip On Flange Price Per Kg, 17-4 PH SS Weldneck Flanges Weight Calculator, DIN 1.4542 Reducing Flanges Price List, SS 17-4 PH Groove & Tongue Flanges Price Per Kg, UNS S17400 WNRF Flanges Price List In India, Stainless Steel 17-4 PH Square Flanges Price List, 17-4 PH SS Weldo / Nipo Flanges At Factory Price, ASTM A182 SS 17-4 PH Forged Flanges Weight Chart, ASME SA182 SS 17-4 PH Spectacle Blind Flanges Weight Chart.

Stainless Steel 17-4 PH Blind Flange Stockist in UK, UNS S17400 Lap Joint Flanges Manufacturer in Singapore, SS 17-4 PH Longweld Neck Flange Supplier in Qatar, ASME SA182 SS 17-4 PH Spectacle Blind Flanges Exporter in Lebanon, DIN 1.4542 Ring Type Joint Flanges Supplier in Jordan, 17-4 PH SS Spades Ring Spacers Flanges Manufacturer in Tunisia, 17-4 PH SS Flat Flanges Stockist in Australia, ASTM A182 SS 17-4 PH Forged Flanges Manufacturer in USA, 17-4 PH SS Weldneck Flanges Exporter in Kuwait, DIN 1.4542 Forging Facing Flanges Supplier in Algeria, ASTM A182 SS 17-4 PH SORF Flanges Supplier in Iraq, DIN 1.4542 Threaded Flanges Stockist in Malaysia

Stainless Steel 17-4 PH Blind Flange Stockist in UK, UNS S17400 Orifice Flanges Exporter in South Africa, SS 17-4 PH SWRF Flanges Manufacturer in Israel, SS 17-4 PH Weld Necl Flanges A/ B Exporter in Yemen, ASTM A182 SS 17-4 PH Forged Flanges Manufacturer in USA, Stainless Steel 17-4 PH Flanges Bolts Exporter in Syria, 17-4 PH SS Flat Flanges Stockist in Australia, ASME SA182 SS 17-4 PH Spectacle Blind Flanges Exporter in Lebanon, SS 17-4 PH Slip On Flange Supplier in Saudi Arabia, DIN 1.4542 Forging Facing Flanges Supplier in Algeria, DIN 1.4542 RTJ Flanges Stockist in UK, 17-4 PH SS Weldneck Flanges Exporter in Kuwait.

Stainless Steel Flanges

- Stainless Steel 304/ 304L/ 304H Flanges

- Stainless Steel 309 Flanges

- Stainless Steel 310/ 310S Flanges

- Stainless Steel 316/ 316L/ 316Ti Flanges

- Stainless Steel 317/317L Flanges

- Stainless Steel 321 Flanges

- Stainless Steel 347/ 347H Flanges

- Stainless Steel 410/ 420/ 430 Flanges

- Stainless Steel 446 Flanges

- Stainless Steel 904L Flanges

- Stainless Steel 15-5 PH Flanges

- Stainless Steel 17-4 PH Flanges