Nickel 200/201 Fasteners

Nickel 201 Spring Washer, ASME SB160 Nickel 200 Hex Nuts, 201 Nickel Rivet Nuts, 200 Nickel Countersunk Bolts, DIN 2.4068 Tab Washer, UNS N02201 Plain Washer, DIN 2.4066 Torx Bolts.

About Nickel 200/201 Fasteners

Nissan Steel supplies Nickel 200/201 Fasteners more than anyone else. We are the most well-known and famous company that sells all kinds of nickel fasteners. We offer it in all shapes, sizes, thicknesses, and dimensions to meet customers’ needs worldwide. Nickel is a natural element that comes from the center of the earth. It is a silvery-white hue with a golden undertone and a glossy finish. It can be twisted without fracturing and doesn’t corrode.

Nickel alloys and other metals are forged into malleable rivets called nickel alloys. It’s resistant to corrosion and can be used in extreme conditions. The characteristics of economically pure cast nickel 200 and 201 are identical. There are many different nickel fasteners, such as Nickel Alloy stud bolts, flat washers, lock nuts, square bolts, double-ended studs, square nuts, cap screws, fender washers, and nuts. Nickel 200/201 Fasteners are made of non-ferrous metals that don’t rust and have high strength, toughness, and resistance to high temperatures. Because of these qualities, they are often used in exhaust systems, engine parts, and other high-heat equipment. They are also used in pump and valve parts, marine and saltwater equipment, food processing, and serving equipment.

Nickel fasteners are used to connect two parts to hold them together. It’s easy to take apart, and the pieces fit together without damage. With these stronger fasteners, you can make a connection that can last forever. They are used when there needs to be a minimum amount of pressure and no leaks. Nickel 200/201 Fasteners have good resistance at a wide range of temperatures that are not ideal. These nickel fasteners are used with both inorganic and organic compounds and are good at dealing with most harsh chemicals.

Tests like a creep, compression, proof load, axial, etc., are done. Boxes, or cartons, are used for the packaging. Each one is also wrapped in a thin piece of plastic to protect it from damage from the outside.

DIN 2.4068 Tab Washer Manufacturer, 200 Nickel Countersunk Bolts Stockist, UNS N02201 Plain Washer Exporter, Nickel 201 Spring Washer Stockist.

Specification of Nickel 200/201 Fasteners

| Specifications | ASTM B160 / ASME SB160 |

| Standard | DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Size | M3 - M100 | 3/6″ - 4″ | Custom Sizes |

| Fasteners Length | 3 mm - 200 mm | Custom Sizes |

| Nuts Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Washers Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads available | UNF, BSW, BSF, METRIC, UNC, or as required |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Manufacturing Process | Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

Ready stock of available for Nickel 200/201 Fasteners

Equivalent Grades of Nickel 200/201 Fasteners

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | НП-2 | – | LC-Ni 99 |

Chemical Composition of Nickel 200/201 Fasteners

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Mechanical Properties of Nickel 200/201 Fasteners

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 200 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

| Nickel 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Other Types of Nickel 200/201 Fasteners

Dimensions Standard Of Nickel 200/201 Fasteners

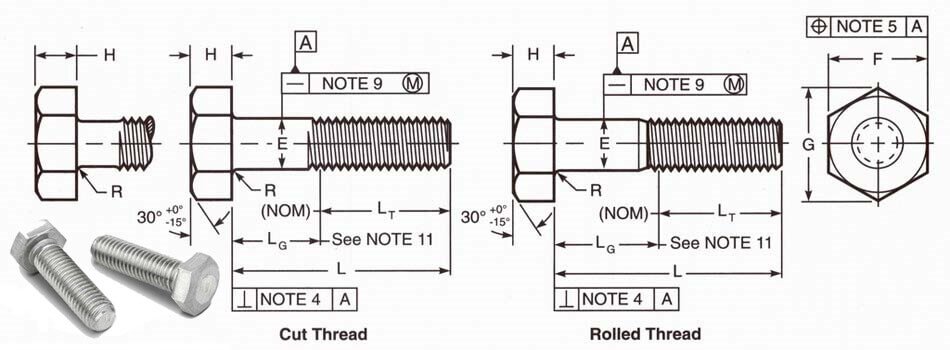

Dimensions Chart of Bolts

| Nominal Size or Basic Product Diameter | Full-Size Body Diameter, E | Width Across Flats, F | Width Across Corners, G | Head Height, H Basic | Radius of Fillet, R | Nominal Thread Length for Bolt Lengths, LT |

|||||||||

| inch | mm | Max | Min | Basic inch | Max | Min | Max | Min | Basic inch | Max | Min | Max | Min | 6 in. and Shoter | Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

Dimensions Chart of Stud Bolts

| Nominal Size Diameter, D inch | Tap End Full Thread Length, BM | Umax = 2P | Minimum Nut End Full Thread Length, Bmin |

||||||

| Nominal | Min. | Max. | UNC & NC-5 Thread | UNF Thread | 8UN Thread | L ≤ 10 | 10 < L ≤ 16 | L > 16 | |

| 1/4 | 0.375 | 0.350 | 0.400 | 0.100 | 0.071 | ... | 0.750 | 1.000 | 1.500 |

| 5/16 | 0.469 | 0.440 | 0.498 | 0.111 | 0.083 | -- | 0.875 | 1.125 | 1.625 |

| 3/8 | 0.563 | 0.532 | 0.594 | 0.125 | 0.083 | -- | 1.000 | 1.250 | 1.750 |

| 7/16 | 0.656 | 0.620 | 0.692 | 0.143 | 0.100 | -- | 1.125 | 1.375 | 1.875 |

| 1/2 | 0.750 | 0.708 | 0.792 | 0.154 | 0.100 | -- | 1.250 | 1.500 | 2.000 |

| 9/16 | 0.844 | 0.802 | 0.896 | 0.167 | 0.111 | -- | 1.375 | 1.625 | 2.125 |

| 5/8 | 0.938 | 0.892 | 0.983 | 0.182 | 0.111 | -- | 1.500 | 1.750 | 2.250 |

| 3/4 | 1.1.25 | 1.075 | 1.175 | 0.200 | 0.125 | -- | 1.750 | 2.000 | 2.500 |

| 7/8 | 1.313 | 1.258 | 1.368 | 0.222 | 0.143 | -- | 2.000 | 2.250 | 2.750 |

| 1 | 1.500 | 1.438 | 1.562 | 0.250 | 0.167 | -- | 2.250 | 2.500 | 3.000 |

| 1 1/8 | 1.688 | 1.625 | 1.750 | 0.286 | 0.167 | 0.250 | 2.500 | 2.750 | 3.250 |

| 1 1/4 | 1.875 | 1.813 | 1.938 | 0.286 | 0.167 | 0.250 | 2.750 | 3.000 | 3.500 |

| 1 3/8 | 2.063 | 2.000 | 2.125 | 0.333 | 0.167 | 0.250 | 3.000 | 3.250 | 3.750 |

| 1 1/2 | 2.250 | 2.188 | 2.313 | 0.333 | 0.167 | 0.250 | 3.250 | 3.500 | 4.000 |

| 1 5/8 | 2.438 | 2.375 | 2.500 | -- | -- | 0.250 | 3.500 | 3.750 | 4.250 |

| 1 3/4 | 2.625 | 2.563 | 2.688 | 0.400 | -- | 0.250 | 3.750 | 4.000 | 4.500 |

| 1 7/8 | 2.813 | 2.750 | 2.875 | -- | -- | 0.250 | 4.000 | 4.250 | 4.750 |

| 2 | 3.000 | 2.925 | 3.075 | 0.444 | -- | 0.250 | 4.250 | 4.500 | 5.000 |

| 2 1/4 | 3.375 | 3.300 | 3.450 | 0.444 | -- | 0.250 | 4.750 | 5.000 | 5.500 |

| 2 1/2 | 3.750 | 3.675 | 3.825 | 0.500 | -- | 0.250 | 5.250 | 5.500 | 6.000 |

| 2 3/4 | 4.125 | 4.050 | 4.200 | 0.500 | -- | 0.250 | 5.750 | 6.000 | 6.500 |

| 3 | 4.500 | 4.425 | 4.575 | 0.500 | -- | 0.250 | -- | 6.500 | 7.000 |

| 3 1/4 | 4.875 | 4.775 | 4.975 | 0.500 | -- | 0.250 | -- | 7.000 | 7.500 |

| 3 1/2 | 5.250 | 5.150 | 5.350 | 0.500 | -- | 0.250 | -- | 7.500 | 8.000 |

| 3 3/4 | 5.625 | 5.525 | 5.725 | 0.500 | -- | 0.250 | -- | 8.000 | 8.500 |

| 4 | 6.000 | 5.900 | 6.100 | 0.500 | -- | 0.250 | -- | 8.500 | 9.000 |

Dimensions Chart of Nuts

| Nominal Size inch | Basic Major Diameter of Thread | Width Across Flats, F | Width Across Corners, G | Thickness Heavy Hex Nuts, H | Thickness Heavy Hex Jam Nuts, H1 | Maximum Runout of Bearing Surface to Thread Axis, FIM |

|||||||||

| Heavy HEX NUTS | Heavy Hex Jam Nuts |

||||||||||||||

| Specified Proof load | |||||||||||||||

| Basic inch | Min. | Max | Min. | Max | Basic inch | Min. | Max | Basic inch | Min. | Max | Up to 150,000 psi | 150,000 psi and Greater | All Strength Levels |

||

| 1/4 | 0.2500 | 1/2 | 0.488 | 0.500 | 0.556 | 0.577 | 15/64 | 0.218 | 0.250 | 11/64 | 0.156 | 0.188 | 0.017 | 0.011 | 0.017 |

| 5/16 | 0.3125 | 9/16 | 0.546 | 0.562 | 0.622 | 0.650 | 19/64 | 0.280 | 0.314 | 13/64 | 0.186 | 0.220 | 0.020 | 0.012 | 0.020 |

| 3/8 | 0.3750 | 11/16 | 0.669 | 0.688 | 0.763 | 0.794 | 23/64 | 0.341 | 0.377 | 15/64 | 0.216 | 0.252 | 0.021 | 0.014 | 0.021 |

| 7/16 | 0.4375 | 3/4 | 0.728 | 0.750 | 0.830 | 0.866 | 27/64 | 0.403 | 0.441 | 17/64 | 0.247 | 0.285 | 0.022 | 0.015 | 0.022 |

| 1/2 | 0.5000 | 7/8 | 0.850 | 0.875 | 0.969 | 1.010 | 31/64 | 0.464 | 0.504 | 19/64 | 0.277 | 0.317 | 0.023 | 0.016 | 0.023 |

| 9/16 | 0.5625 | 15/16 | 0.909 | 0.938 | 1.037 | 1.083 | 35/64 | 0.526 | 0.568 | 21/64 | 0.307 | 0.349 | 0.024 | 0.017 | 0.024 |

| 5/8 | 0.6250 | 1 1/16 | 1.031 | 1.062 | 1.175 | 1.227 | 39/64 | 0.587 | 0.631 | 23/64 | 0.337 | 0.381 | 0.025 | 0.018 | 0.025 |

| 3/4 | 0.7500 | 1 1/4 | 1.212 | 1.250 | 1.382 | 1.443 | 47/64 | 0.710 | 0.758 | 27/64 | 0.398 | 0.446 | 0.027 | 0.020 | 0.027 |

| 7/8 | 0.8750 | 1 7/16 | 1.394 | 1.438 | 1.589 | 1.660 | 55/64 | 0.833 | 0.885 | 31/64 | 0.458 | 0.510 | 0.029 | 0.022 | 0.029 |

| 1 | 1.0000 | 1 5/8 | 1.575 | 1.625 | 1.796 | 1.876 | 63/64 | 0.956 | 1.012 | 35/64 | 0.519 | 0.575 | 0.031 | 0.024 | 0.031 |

| 1 1/8 | 1.1250 | 1 13/16 | 1.756 | 1.812 | 2.002 | 2.093 | 1 7/64 | 1.079 | 1.139 | 39/64 | 0.579 | 0.639 | 0.033 | 0.027 | 0.033 |

| 1 1/4 | 1.2500 | 2 | 1.938 | 2.000 | 2.209 | 2.309 | 1 7/32 | 1.187 | 1.251 | 23/32 | 0.687 | 0.751 | 0.035 | 0.030 | 0.035 |

| 1 3/8 | 1.3750 | 2 3/16 | 2.119 | 2.188 | 2.416 | 2.526 | 1 11/32 | 1.310 | 1.378 | 25/32 | 0.747 | 0.815 | 0.038 | 0.033 | 0.038 |

| 1 1/2 | 1.5000 | 2 3/8 | 2.300 | 2.375 | 2.622 | 2.742 | 1 15/32 | 1.433 | 1.505 | 27/32 | 0.808 | 0.880 | 0.041 | 0.036 | 0.041 |

| 1 5/8 | 1.6250 | 2 9/16 | 2.481 | 2.562 | 2.828 | 2.959 | 1 19/32 | 1.556 | 1.632 | 29/32 | 0.868 | 0.944 | 0.044 | 0.038 | 0.044 |

| 1 3/4 | 1.7500 | 2 3/4 | 2.662 | 2.750 | 3.035 | 3.175 | 1 23/32 | 1.679 | 1.759 | 31/32 | 0.929 | 1.009 | 0.048 | 0.041 | 0.048 |

| 1 7/8 | 1.8750 | 2 15/16 | 2.844 | 2.938 | 3.242 | 3.392 | 1 27/32 | 1.802 | 1.886 | 1 1/32 | 0.989 | 1.073 | 0.051 | 0.044 | 0.051 |

| 2 | 2.0000 | 3 1/8 | 3.025 | 3.125 | 3.449 | 3.608 | 1 31/32 | 1.925 | 2.013 | 1 3/32 | 1.050 | 1.138 | 0.055 | 0.047 | 0.055 |

| 2 1/4 | 2.2500 | 3 1/2 | 3.388 | 3.500 | 3.862 | 4.041 | 2 13/64 | 2.155 | 2.251 | 1 13/64 | 1.155 | 1.251 | 0.061 | 0.052 | 0.061 |

| 2 1/2 | 2.5000 | 3 7/8 | 3.750 | 3.875 | 4.275 | 4.474 | 2 29/64 | 2.401 | 2.505 | 1 29/64 | 1.401 | 1.505 | 0.068 | 0.058 | 0.068 |

| 2 3/4 | 2.7500 | 4 1/4 | 4.112 | 4.250 | 4.688 | 4.907 | 2 45/64 | 2.647 | 2.759 | 1 37/64 | 1.522 | 1.634 | 0.074 | 0.064 | 0.074 |

| 3 | 3.0000 | 4 5/8 | 4.475 | 4.625 | 5.102 | 5.340 | 2 61/64 | 2.893 | 3.013 | 1 45/64 | 1.643 | 1.763 | 0.081 | 0.070 | 0.081 |

| 3 1/4 | 3.2500 | 5 | 4.838 | 5.000 | 5.515 | 5.774 | 3 3/16 | 3.124 | 3.252 | 1 13/16 | 1.748 | 1.876 | 0.087 | 0.075 | 0.087 |

| 3 1/2 | 3.5000 | 5 3/8 | 5.200 | 5.375 | 5.928 | 6.207 | 3 7/16 | 3.370 | 3.506 | 1 15/16 | 1.870 | 2.006 | 0.094 | 0.081 | 0.094 |

| 3 3/4 | 3.7500 | 5 3/4 | 5.562 | 5.750 | 6.341 | 6.640 | 3 11/16 | 3.616 | 3.760 | 2 1/16 | 1.990 | 2.134 | 0.100 | 0.087 | 0.100 |

| 4 | 4.0000 | 6 1/8 | 5.925 | 6.125 | 6.755 | 7.073 | 3 15/16 | 3.862 | 4.014 | 2 3/16 | 2.112 | 2.264 | 0.107 | 0.093 | 0.107 |

Dimensions Chart of Washer

| Nominal Size | T | Clipped Width E, Min. | |||||||

| I.D. | O.D. | Standard | Extra Thick | ||||||

| [Note (1)] | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | [Note (2)] |

| 12 | 14.4 | 14 | 27 | 25.7 | 4.6 | 3.1 | 10 | 8 | 10.5 |

| 16 | 18.4 | 18 | 34 | 32.4 | 4.6 | 3.1 | 10 | 8 | 14 |

| 20 | 22.5 | 22 | 42 | 40.4 | 4.6 | 3.1 | 10 | 8 | 17.5 |

| 22 | 24.5 | 24 | 44 | 42.4 | 4.6 | 3.4 | 10 | 8 | 19.2 |

| 24 | 26.5 | 26 | 50 | 48.4 | 4.6 | 3.4 | 10 | 8 | 21 |

| 27 | 30.5 | 30 | 56 | S4.1 | 4.6 | 3.4 | 10 | 8 | 23.6 |

| 30 | 33.6 | 33 | 60 | 58.1 | 4.6 | 3.4 | 10 | 8 | 26.2 |

| 36 | 39.6 | 39 | 72 | 70.1 | 4.6 | 3.4 | 10 | 8 | 31.S |

| 42 | 45.6 | 45 | 84 | 81.8 | 7.2 | 4.6 | 10 | 8 | 36.7 |

| 48 | 52.7 | 52 | 95 | 92.8 | 7.2 | 4.6 | 10 | 8 | 42 |

| 56 | 62.7 | 62 | 107 | 104.8 | 8.7 | 6.1 | 10 | 8 | 49 |

| 64 | 70.7 | 70 | 118 | 115.8 | 8.7 | 6.1 | 10 | 8 | 56 |

| 72 | 78.7 | 78 | 130 | 127.5 | 8.7 | 6.1 | 10 | 8 | 63 |

| 80 | 86.9 | 86 | 142 | 139.5 | 8.7 | 6.1 | 10 | 8 | 70 |

| 90 | 96.9 | 96 | 159 | 156.5 | 8.7 | 6.1 | 10 | 8 | 78.7 |

| 100 | 107.9 | 107 | 176 | 173.5 | 8.7 | 6.1 | 10 | 8 | 87.5 |

Size Of Nickel 200/201 Fasteners

Metric Bolt Dimensions Chart

Imperial Bolt Dimensions Chart

Size Chart of Nuts

| Nut Size (mm) | Diameter* (mm) | Height (mm) |

||

| Hex Nut | Jam Nut | Nylock Nut | ||

| 2 | 4 | 1.6 | 1.2 | - |

| 2.5 | 5 | 2 | 1.6 | - |

| 3 | 5.5 | 2.4 | 1.8 | 4 |

| 4 | 7 | 3.2 | 2.2 | 5 |

| 5 | 8 | 4 | 2.7 | 5 |

| 6 | 10 | 5 | 3.2 | 6 |

| 7 | 11 | 5.5 | 3.5 | - |

| 8 | 13 | 6.5 | 4 | 8 |

| 10 | 17 | 8 | 5 | 10 |

| 12 | 19 | 10 | 6 | 12 |

| 14 | 22 | 11 | 7 | 14 |

| 16 | 24 | 13 | 8 | 16 |

| 18 | 27 | 15 | 9 | 18.5 |

| 20 | 30 | 16 | 10 | 20 |

Size Chart of Washers

| SIZE | INSIDE DIAMETER | OUTSIDE DIAMETER | THICKNESS |

| SAE FLAT WASHERS | |||

| #6 | 5/32" | 3/8" | 3/64" |

| #8 | 3/16" | 7/16" | 3/64" |

| #10 | 7/32" | 1/2" | 3/64" |

| 1/4 | 9/32" | 5/8" | 1/16" |

| 5/16 | 11/32" | 11/16" | 1/16" |

| 3/8 | 13/32" | 13/16" | 1/16" |

| 7/16 | 15/32" | 59/64" | 1/16" |

| 1/2 | 17/32" | 1-1/16" | 3/32" |

| 9/16 | 19/32" | 1-3/16" | 3/32" |

| 5/8 | 21/32" | 1-5/16" | 3/32" |

| 3/4 | 13/16" | 1-1/2" | 9/64" |

| 7/8 | 15/16" | 1-3/4" | 9/64" |

| 1" | 1-1/16" | 2" | 9/64" |

| 1-1/8 | 1-3/16" | 2-1/4" | 9/64" |

| 1-1/4 | 1-5/16" | 2-1/2" | 5/32" |

| 1-1/2 | 1-7/16" | 3" | 3/16" |

| USS FLAT WASHERS | |||

| 3/16 | 1/4" | 9/16" | 3/64" |

| 1/4 | 5/16" | 3/4" | 1/16" |

| 5/16 | 3/8" | 7/8" | 5/64" |

| 3/8 | 7/16" | 1" | 5/64" |

| 7/16 | 1/2" | 1-1/4" | 5/64" |

| 1/2 | 9/16" | 1-3/8" | 7/64" |

| 9/16 | 5/8" | 1-1/2" | 7/64" |

| 5/8 | 11/16" | 1-3/4" | 9/64" |

| 3/4 | 13/16" | 2" | 5/32" |

| 7/8 | 15/16" | 2-1/4" | 11/64" |

| 1" | 1-1/16" | 2-1/2" | 11/64" |

| 1-1/8 | 1-1/4" | 2-3/4" | 11/64" |

| 1-1/4 | 1-3/8" | 3" | 11/64" |

| 1-3/8 | 1-1/2" | 3-1/4" | 3/16" |

| 1-1/2 | 1-5/8" | 3-1/2" | 3/16" |

| 1-5/8 | 1-3/4" | 3-3/4" | 3/16" |

| 1-3/4 | 1-7/8" | 4" | 3/16" |

| 1-7/8 | 2" | 4-1/4" | 3/16" |

| 2" | 2-1/8" | 4-1/2" | 3/16" |

| 2-1/2 | 2-5/8" | 5" | 15/64" |

| 3" | 3-1/8" | 5-1/2" | 9/32" |

Weight Chart Of Nickel 200/201 Fasteners

| LENGTHS | #2 | #3 | #4 | #5 | #6 | #8 | #10 | #12 | 1/4″ | 5/16″ | 3/8″ |

| 1/8 | 0.40 | 0.55 | 0.70 | 1.1 | 1.4 | — | — | — | — | — | — |

| 3/16 | 0.50 | 0.70 | 0.90 | 1.2 | 1.5 | 2.5 | 3.9 | — | — | — | — |

| 1/4 | 0.60 | 0.80 | 1.00 | 1.4 | 1.7 | 2.8 | 4.3 | 5.6 | 8.5 | — | — |

| 5/16 | 0.60 | 0.90 | 1.20 | 1.5 | 1.9 | 3.1 | 4.6 | 6.1 | 9.1 | 16.7 | — |

| 3/8 | 0.70 | 0.90 | 1.30 | 1.7 | 2.1 | 3.4 | 5.0 | 6.5 | 9.8 | 17.7 | 29.2 |

| 7/16 | 0.80 | 1.00 | 1.50 | 1.9 | 2.2 | 3.6 | 5.4 | 6.9 | 10.4 | 18.8 | 30.7 |

| 1/2 | 0.80 | 1.10 | 1.60 | 2.0 | 2.4 | 3.9 | 5.8 | 7.4 | 11.1 | 19.8 | 32.2 |

| 9/16 | 0.90 | 1.20 | 1.70 | 2.2 | 2.6 | 4.2 | 6.2 | 7.8 | 11.7 | 20.9 | 33.6 |

| 5/8 | 1.00 | 1.30 | 1.80 | 2.3 | 2.8 | 4.5 | 6.6 | 8.3 | 12.4 | 21.9 | 35.1 |

| 3/4 | 1.10 | 1.50 | 2.10 | 2.6 | 3.2 | 5.0 | 7.3 | 9.2 | 13.6 | 24.0 | 38.0 |

| 7/8 | 1.30 | 1.70 | 2.30 | 3.0 | 3.5 | 5.6 | 8.1 | 10.1 | 14.9 | 26.1 | 41.0 |

| 1″ | 1.40 | 1.90 | 2.50 | 3.4 | 3.9 | 6.2 | 8.9 | 11.0 | 16.1 | 28.8 | 44.0 |

| 1-1/8″ | 1.50 | 2.00 | 2.80 | 3.8 | 4.3 | 6.7 | 9.6 | 11.9 | 17.4 | 30.2 | 47.0 |

| 1-1/4″ | 1.60 | 2.20 | 3.00 | 4.1 | 4.6 | 7.3 | 10.4 | 12.8 | 18.7 | 32.3 | 49.8 |

| 1-1/2″ | 1.80 | 2.50 | 3.50 | 4.7 | 5.3 | 8.3 | 11.9 | 14.7 | 21.2 | 36.5 | 55.8 |

| 1-3/4″ | 2.10 | 2.90 | 4.00 | 5.3 | 6.1 | 9.4 | 13.5 | 16.5 | 23.7 | 40.7 | 61.7 |

| 2″ | 2.40 | 3.30 | 4.50 | 6.0 | 6.8 | 10.6 | 15.0 | 18.3 | 26.2 | 44.8 | 67.6 |

| 2-1/4″ | 2.60 | 3.60 | 5.00 | 6.7 | 7.6 | 11.8 | 16.6 | 20.1 | 28.8 | 19.0 | 73.5 |

| 2-1/2″ | 2.80 | 3.90 | 5.50 | 7.3 | 8.3 | 12.9 | 18.1 | 22.0 | 31.3 | 53.2 | 79.5 |

| 2-3/4″ | 3.10 | 4.30 | 6.00 | 7.9 | 9.1 | 13.9 | 19.7 | 23.8 | 33.9 | 57.3 | 85.3 |

| 3″ | 3.40 | 4.70 | 6.50 | 8.6 | 9.8 | 15.0 | 21.2 | 25.6 | 36.4 | 61.5 | 91.3 |

industrial use fitting for Nickel 200/201 Fasteners

Price Of Nickel 200/201 Fasteners

| High Nickel Alloys Hex Bolt | USD $8.11 - $20.21 / kg (FOB Price) on request |

| High Nickel Alloys Hex Nut | USD $8.11 - $20.21 / kg (FOB Price) on request |

| High Nickel Alloys Screw | USD $8.11 - $20.21 / kg (FOB Price) on request |

| High Nickel Alloys Spring Washer | USD $8.11 - $20.21 / kg (FOB Price) on request |

| High Nickel Alloys Stud Bolt | USD $8.11 - $20.21 / kg (FOB Price) on request |

Application Of Nickel 200/201 Fasteners

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Nickel 200/201 Fasteners

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Nickel 200/201 Fasteners

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

DIN 2.4068 Tab Washer Price List, 200 Nickel Hex Head Bolts Weight Calculator, Nickel 200 T Nuts At Factory Price, Nickel 201 Spring Washer Price Per Kg, DIN 2.4066 Torx Bolts Catalogue, ASTM B160 Nickel 200 Hex Bolts Weight Chart, Nickel 200 Stud Bolts Price Per Kg, UNS N02200 Forged Hook Bolts Price List In India, 201 Nickel Rivet Nuts At Factory Price, ASME SB160 Nickel 200 Hex Nuts At Factory Price, Nickel Alloys 201 Carriage Bolts Price List, UNS N02201 Plain Washer Weight Chart.

DIN 2.4068 Star washer Supplier in Tamilnadu, Nickel 201 Roofing screws Manufacturer in Lucknow, UNS N02201 Captive-nuts Stockist in Karnataka, UNS N02200 Drywall screw Manufacturer in Daman, 201 Nickel 12 point nut Stockist in Kerla, 200 Nickel Square washer Manufacturer in Ahmedabad, Nickel 201 Lock washer Exporter in Punjab, DIN 2.4066 Self-tapping-screw Stockist in Gujarat, ASTM B160 Nickel 201 Grub screw Supplier in Bihar, ASME SB160 Nickel 200 Sealing washer Exporter in Delhi, Nickel Alloys 200 Pocket hole screws Exporter in Kanpur, UNS N02200 Self drilling screws Stockist in Nagpur.

UNS N02201 Captive-nuts Stockist in Saudi Arabia, Nickel 201 Roofing screws Manufacturer in Israel, ASME SB160 Nickel 200 Sealing washer Exporter in Lebanon, ASTM B160 Nickel 201 Grub screw Supplier in Iraq, 201 Nickel 12 point nut Stockist in Egypt, Nickel Alloys 200 Pocket hole screws Exporter in Iran, DIN 2.4066 Sleeve nuts Supplier in Algeria, UNS N02200 Self drilling screws Stockist in Libya, DIN 2.4068 Star washer Supplier in Jordan, Nickel 200 Wood screws Exporter in Syria, 200 Nickel Square washer Manufacturer in Tunisia, Nickel 201 Lock washer Exporter in Yemen.