Carbon Steel A105 Forged fitting

Carbon Steel A105 Threaded 45 Lateral Tee, A105 Carbon Steel Adaptor, ANSI B16.5 Threaded Plug, ASTM A105 Carbon Steel 45 Degree Elbow, ANSI B16.5 Pipe Nipple, ASME SA105 Carbon Steel A105 Reducer Insert.

About Carbon Steel A105 Forged fitting

The ASME SA 105 Carbon Steel Forged Threaded Tee Fittings utilize corrosion-resistant austenitic ferrite steel for situations where standard grades do not provide the required corrosion resistance. Our Carbon Steel A105 Screwed Threaded Pipe Reducers contain low levels of carbon, manganese, and silicon, making them suitable for non-critical pressure applications that operate at constant temperatures, such as refrigeration fittings. These low-carbon reducers offer high levels of machinability and weldability. Compared to other steels, ASTM A105 Carbon Steel Forged Threaded Cross Fittings contain higher proportions of tungsten and copper in their composition, making them able to withstand harsh conditions, including chlorides. Oxyacetylene welding is not recommended with ASTM A105 Carbon Steel Forged Threaded Elbow Fittings, as it can lead to carbon pick-up in the weld region.

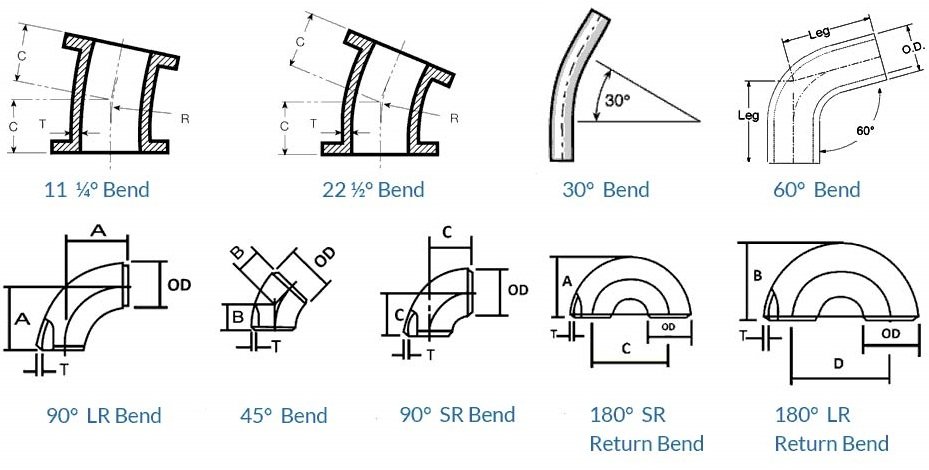

On the other hand, electric arc welding procedures are appropriate for use with these fittings. The product quality has been significantly improved by utilizing the physical, chemical, and mechanical properties of forged fittings, and our predetermined standards have certain restrictions. The thickness and weight of these forged fittings should fall within a specific range and stay within that range. Our rigorous in-house standards govern the chemistry and manufacture of ASTM A105 Carbon Steel Forged Threaded Bend Fittings. The annealing process transforms the material into the desired shape, and the fittings are quenched, making the product suitable for liquid mediums. Our stricter in-house standards govern the chemistry and manufacturing of ASTM A105 Carbon Steel Polished Threaded Bend Fittings. The heat treatment processes, including tempering, normalizing, and annealing, are performed on the product, along with tempering and quenching. Industries that use these ASTM A105 Carbon Steel Forged Fittings include the structural pipe business, fabrication, food processing, and power plant-related industriesNissan Steel supplies a variety of Carbon Steel ASTM A105 Forged Components, including Equal Tee, Coupling, and Pipe Cap. Nissan Steel offers various configurations for Carbon Steel ASTM A105 Forged Fittings, including A105 Carbon Steel Equal Tee, ASTM A105 Carbon Steel Coupling, and Carbon Steel Pipe Cap.

Carbon A105 Threaded Swage Nipple Exporter, ANSI B16.5 Pipe Nipple Exporter, A105 Carbon Steel Union Exporter, Carbon Steel A105 Threaded 45 Lateral Tee Exporter.

Specification of Carbon Steel A105 Forged fitting

| Specification | ASTM A105 / ASME SA105 |

| Dimension Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Size | 1/8" NB to 4" NB |

| Type | Socketweld Fittings, Screwed-Threaded Fittings |

| Pressure-Temperature Class | Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS. |

Ready stock of available for Carbon Steel A105 Forged fitting

Chemical Composition of Carbon Steel A105 Forged fitting

| Grade | C | Si | Mn | P | S | Mo | Ni | Cr | Cu | V |

| A105 | 0.35 | 0.10–0.35 | 0.60–1.05 | 0.035 | 0.040 | 0.12 | 0.40 | 0.30 | 0.40 | 0.08 |

Mechanical Properties of Carbon Steel A105 Forged fitting

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Other Types of Carbon Steel A105 Forged fitting

Dimensions Standard Of Carbon Steel A105 Forged fitting

| ASME b16.9 Fittings Normal Pipe Size | ANSI b16 9 Pipe Fitting O D Y | Wall Thickness T (Pipe Elbow Sch.) | LR 45 Deg Elbows Centre to Face B | SR 45 Deg Elbows Weight | LR 90 Deg Elbows Centre to Face A | LR 90 Deg Elbows Weight In Below | SR 90 Deg Elbows Centre to Face A | SR 90 Deg Elbows Weight In Below | ||

| mm | inch | mm | mm | Schedule | mm | kg | mm | kg | mm | kg |

| 15 | 1/2” | 21.3 | 2.78 | STD | 15.9 | 0.04 | 38.1 | 0.08 | – | – |

| 3.73 | X.S | 15.9 | 0.05 | 38.1 | 0.10 | – | – | |||

| 20 | 3/4” | 26.7 | 2.87 | STD | 11.1 | 0.04 | 28.6 | 0.08 | – | – |

| 3.91 | X.S | 11.1 | 0.05 | 28.6 | 0.11 | – | – | |||

| 25 | 1” | 33.4 | 3.38 | STD | 22.2 | 0.09 | 38.1 | 0.15 | 25.4 | 0.11 |

| 4.55 | X.S | 22.2 | 0.11 | 38.1 | 0.19 | 25.4 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 25.4 | 0.14 | 47.6 | 0.28 | 31.75 | 0.18 |

| 4.85 | X.S | 25.4 | 0.2 | 47.6 | 0.39 | 31.75 | 0.24 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 28.6 | 0.2 | 57.1 | 0.4 | 38.1 | 0.26 |

| 5.08 | X.S | 28.6 | 0.25 | 57.1 | 0.5 | 38.1 | 0.35 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 34.9 | 0.36 | 76.2 | 0.72 | 50.8 | 0.5 |

| 5.54 | X.S | 34.9 | 0.5 | 76.2 | 1.0 | 50.8 | 0.68 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 44.4 | 0.73 | 95.2 | 1.46 | 63.5 | 0.95 |

| 7.01 | X.S | 44.4 | 0.91 | 95.2 | 1.82 | 63.5 | 1.27 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 50.8 | 1.1 | 114.3 | 2.18 | 76.2 | 1.45 |

| 7.62 | X.S | 50.8 | 1.45 | 114.3 | 2.86 | 76.2 | 1.95 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 63.5 | 2.1 | 152.4 | 4.2 | 101.6 | 2.8 |

| 8.56 | X.S | 63.5 | 2.9 | 152.4 | 5.7 | 101.6 | 3.9 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 79.4 | 3.4 | 190.0 | 6.8 | 127.0 | 4.8 |

| 9.5 | X.S | 79.4 | 5.0 | 190.0 | 10.0 | 127.0 | 6.5 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 95.2 | 5.1 | 229.0 | 10.1 | 152.4 | 6.8 |

| 10.97 | X.S | 95.2 | 7.7 | 229.0 | 15.3 | 152.4 | 10.2 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 127.0 | 10.2 | 305.0 | 20.4 | 203.0 | 13.6 |

| 12.7 | X.S | 127.0 | 15.5 | 305.0 | 30.9 | 203.0 | 20.9 | |||

| 250 | 10” | 273.9 | 9.27 | STD | 159.0 | 18.1 | 381.0 | 36.1 | 254.0 | 24.1 |

| 12.7 | X.S | 159.0 | 24.4 | 381.0 | 48.8 | 254.0 | 32.5 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 190.0 | 26.6 | 457.0 | 53.1 | 305.0 | 35.4 |

| 12.7 | X.S | 190.0 | 35.0 | 457.0 | 70.0 | 305.0 | 46.7 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 222.0 | 34.1 | 533.0 | 68.1 | 356.0 | 45.4 |

| 12.7 | X.S | 222.0 | 45.0 | 533.0 | 90.0 | 356.0 | 60.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 254.0 | 45.0 | 610.0 | 89.3 | 406.0 | 59.5 |

| 12.7 | X.S | 254.0 | 59.0 | 610.0 | 118.0 | 406.0 | 78.7 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 286.0 | 56.5 | 686.0 | 113.0 | 457.0 | 75.6 |

| 12.7 | X.S | 286.0 | 75.0 | 686.0 | 150.0 | 457.0 | 100.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 318.0 | 85.0 | 762.0 | 140.0 | 508.0 | 93.5 |

| 12.7 | X.S | 318.0 | 112.5 | 762.0 | 186.0 | 508.0 | 124.0 | |||

| 600 | 24” | 610.00 | 9.52 | STD | 381.0 | 101.5 | 914.0 | 203.0 | 610.0 | 135.0 |

| 12.7 | X.S | 381.0 | 134.5 | 914.0 | 269.0 | 610.0 | 179.0 | |||

Size Of Carbon Steel A105 Forged fitting

| NPS (inch) | Pipe Schedule. | OD (inch) | Wall Thick. (in) | Temperature | ||||

| 100 Fitting | 200 Fitting | 300 Fitting | 400 Fitting | 500 Fitting | ||||

| Allowable Stress | ||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | |

Weight Chart Of Carbon Steel A105 Forged fitting

| Normal Pipe Sizes | A | B | QTY | Weight In KG |

| ¼ | 0.81 | 0.88 | 160 | 0.20 |

| ⁄ | 0.97 | 1.00 | 130 | 0.26 |

| ½ | 1.12 | 1.31 | 100 | 0.57 |

| ¾ | 1.31 | 1.5 | 75 | 0.71 |

| 1 | 1.5 | 1.81 | 40 | 1.08 |

| 1 ¼ | 1.75 | 2.19 | 25 | 1.68 |

| 1 ½ | 2.00 | 2.44 | 18 | 2.38 |

| 2 | 2.38 | 2.97 | 10 | 3.55 |

| 2 ½ | 3.00 | 3.62 | 4 | 6.22 |

| 3 | 3.38 | 4.31 | 2 | 10.36 |

| 4 | 4.19 | 5.75 | 1 | 23.91 |

Pressure Rating Of Carbon Steel A105 Forged fitting

| Pressure-Temperature | |||||

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 - 1 inch. | 1 1/4 - 2 inch. | 2 1/2 - 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

industrial use fitting for Carbon Steel A105 Forged fitting

Price Of Carbon Steel A105 Forged fitting

| Carbon Steel Elbow | USD $3.24 - $10.84 / Piece (FOB Price) on request |

| Carbon Steel Equal Tee | USD $3.24 - $10.84 / Piece (FOB Price) on request |

| Carbon Steel Reducing Tee | USD $3.24 - $10.84 / Piece (FOB Price) on request |

| Carbon Steel Cross | USD $3.24 - $10.84 / Piece (FOB Price) on request |

| Carbon Steel Cap | USD $3.24 - $10.84 / Piece (FOB Price) on request |

Application Of Carbon Steel A105 Forged fitting

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers.

- Petrochemical Industries

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

Testing Of Carbon Steel A105 Forged fitting

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Hydrostatic Analysis

- Pitting Protection Test

- Power Generation Industries

- Positive Material Recognition

Packing Of Carbon Steel A105 Forged fitting

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden crates

A105 Carbon Steel Adaptor Weight Calculator, CS A105 Round Plug Price List, Carbon Steel A105 Hex Plug Price Per Kg, Carbon Steel A105 Sockolet Price List, ANSI B16.5 Reducing Cross Price List In India, ANSI B16.5 Threaded Plug Price List In India, A105 Carbon Steel Union At Factory Price, ANSI B16.5 Pipe Nipple Weight Chart, CS A105 Threaded Bush Catalogue, CS A105 Threaded Street Elbow Catalogue, ASTM A105 Carbon Steel 45 Degree Elbow Weight Chart, Carbon Steel A105 Threaded 45 Lateral Tee Catalogue, Carbon A105 Threaded Swage Nipple Price List, A105 Carbon Steel Threaded Equal Price Per Kg, A105 Carbon Steel Weld Tee Weight Calculator, Carbon A105 90 Degree Elbow Price List.

Carbon Steel A105 Tee Supplier in Coimbatore, ANSI B16.5 Reducing Cross Stockist in Karnataka, A105 Carbon Steel Threaded Equal Manufacturer in Ahmedabad, CS A105 Threaded Lateral Outlet Supplier in Kolkata, Carbon Steel A105 Hex Plug Stockist in Nashik, ASTM A105 Carbon Steel 45 Degree Elbow Manufacturer in Bengaluru, ASME SA105 Carbon Steel A105 Full Coupling Stockist in Chennai, CS A105 Threaded Bush Stockist in Gujarat, ASME SA105 Carbon Steel A105 Reducer Insert Exporter in Delhi, Carbon Steel A105 Threaded 45 Lateral Tee Exporter in Patna, ANSI B16.5 Pipe Nipple Stockist in Bangalore, ASTM A105 Carbon Steel A105 Threaded Hex Nipple Supplier in Bihar.

ASTM A105 Carbon Steel 45 Degree Elbow Manufacturer in USA, A105 Carbon Steel Weld Tee Stockist in Egypt, ANSI B16.5 Reducing Cross Stockist in Saudi Arabia, Carbon A105 90 Degree Elbow Stockist in UK, CS A105 Threaded Street Elbow Supplier in Jordan, ASTM A105 Carbon Steel A105 Threaded Hex Nipple Supplier in Iraq, Carbon Steel A105 Sockolet Exporter in Yemen, ANSI B16.5 Pipe Nipple Exporter in South Africa, A105 Carbon Steel Threaded Equal Manufacturer in Tunisia, Carbon Steel A105 Nipple Branch Outlet Manufacturer in Israel, A105 Carbon Steel Union Exporter in Indonesia, ASME SA105 Carbon Steel A105 Full Coupling Stockist in UAE, Carbon Steel A105 Hex Plug Stockist in Oman.